I get a lot of questions about the arrangement of the vac pipes in the Omega engine bay on the V6 models.

The V6 uses Vacuum for a number of things

Multiram

Air injection

Brake servo

Climate/heater control.

It is important that these pipes are connected correctly and have no leaks to get the best performance/economy from your engine and to guarantee operation of the heating/climate systems. Unfortunately they are often re-fitted incorrectly by garages following work and in some cases some of the pipes may have been in-correctly routed resulting in chafing and the pipes wearing through.

As an example, I know of a 3.0MV6 Omega which when put on the rolling road was producing around 170Bhp, correct fitment of the multiram pipe work restore this to the full 200Bhp plus!

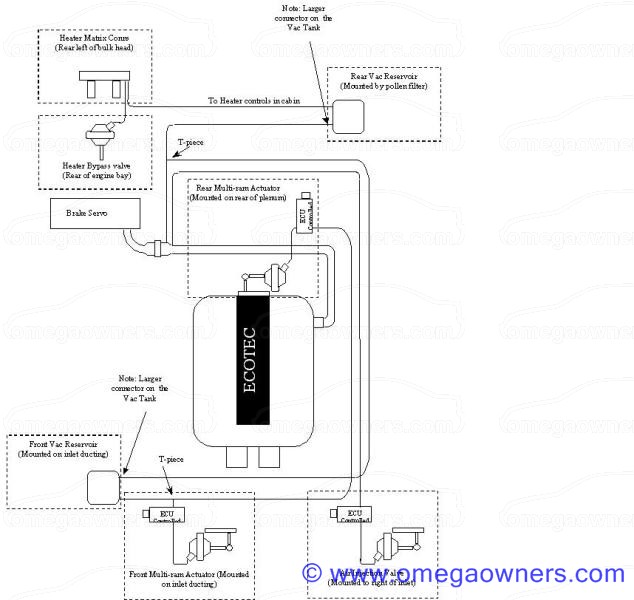

Later setup, identifiable by the presence of a vac tank on the base of the inlet trumpets at the front of the engine bay

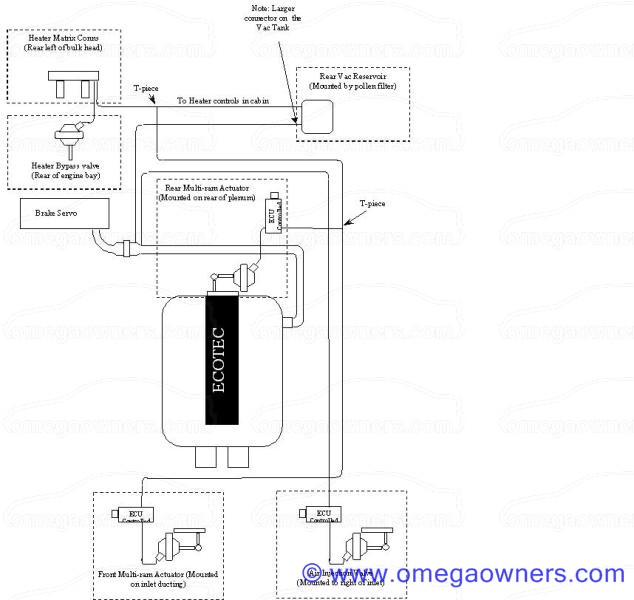

Earlier setup, similar to above but, no separate vac tank for the multiram, instead it is T'ed off the heater vacuum line where it passes through the bulk head.

As an additional note, the following picture shows where the vac pipes pass through the bulk head to the climate/heater controls in the cabin and return to the heater bypass valve.

The connection on the left is the vac feed to the cabin controls and the one on the right is the return which connects to the bypass valve.

I have seen many of these setups where this T-piece has been moved to the brake servo which is great but, at full throttle there is very little vacuum so the multiram stops working

Note also that the vac pipes must be connected correctly to the solenoid valves with the VAC feed connected to the nose connection and the output (to the actuator) on the side connection.

For those with a 4 pot, the setup is very similar with the exclusion of the mulktirams (and air injection on the 2.2)

Author

Topic: V6 engine bay vaccum pipes (Read 41137 times)

Author

Topic: V6 engine bay vaccum pipes (Read 41137 times)